As the 3C industry is flourishing, the demand of cutters is on the increase, especially the great demand of small-diameter cutters. But when it comes to our production of high-precision mircro-diameter cutters, you will probably consider purchasing high-precision CNC grinding machine, grinding wheel, oil, filtration equipment, etc. But have you ever thought of the importance of controlling the oil temperature stability on grinding mircro-diameter cutters?

During processing, what we need is stable temperatures instead of cryogenic temperature. The ensure stable oil temperature is the key in grinding important mircro-diameter cutters. According to our years of experience, we have found out that straight refrigeration is conducive to grinding mircro-diameter cutters

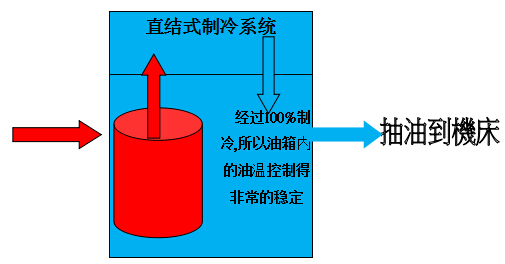

As one of our patents, straight refrigeration realizes refrigeration in a straight way so that 100%’s hot oil will come into the refrigeration system for refrigeration, and then the oil flows into the oil tank. At that time, the oil tank has been cooled completely and without other heat source. Hence the oil temperature is stably controlled.

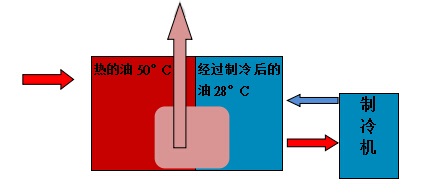

Traditional refrigeration adopts the separation mode which can realize refrigeration but is hard to ensure stable oil temperature!!

From oil pumping to machine tool

(Pump cannot judge the temperature of the pumped neutralized oil so that it is hard to bring about stable temperature difference.)

The separating refrigerating machine realizes refrigeration through neutralization of hot and cold temperature. First, pump the hot oil onto the refrigerating machine for refrigeration and then send it to the oil tank for neutralization with hot oil, before being sent to the machine tool for use by the pump. But the filtering, refrigeration and the machine tool are operated continuously, so that the pump cannot judge the present pumped oil has been neutralized. The pumped oil which can be 50°C or 28°C, will have great temperature error. So given the changing oil temperatures, will you trust the stable oil temperature as promised by other suppliers any more? Obviously they cannot guarantee stable oil temperature, let alone turning out high-precision cutters.

[Patent for invention] We apply the patented straight refrigeration system. Pump all the filtered hot oil into the cooling system for refrigeration. The cooled hot oil flows into the oil tank directly, so the entire oil tank has been cooled and is barely affected by external heat source. For this reason, the stability of oil temperature can be guaranteed, and the oil being pumped into the machine tool has stable temperature.